About : OUR STORY

OUR RIPPLE EFFECT MAKES WAVES

IT ALL STARTED WITH A HANDSHAKE.

About : OUR STORY

OUR RIPPLE EFFECT MAKES WAVES

IT ALL STARTED WITH A HANDSHAKE.

In 1951, Clarence Simmons opened a machine shop in the small West Texas town of Sundown. He provided machining services to the general public and for the booming oil and gas industry. However, he knew he could grow well beyond his humble beginnings.

In 1953, Mr. Simmons hired Raymond Pickering, a visionary and entrepreneur who shared Mr. Simmon’s dream of transforming a small machine shop into a premier manufacturer. Pickering knew, however, expansion could only be maintained through exceptional products – a sentiment which laid the framework for SIMFLO’s quality assurance procedures still in practice today.

With continued growth and success, Mr. Simmons and Mr. Pickering developed their own line of vertical turbine pumps. The first Simmons brand bowl assembly was manufactured and sold in 1956. From that moment on, Simmons products have been manufactured and tested to ensure unmatched quality through uncompromising standards.

Since Mr. Simmons opened his first machine shop, SIMFLO has evolved into a major manufacturer of over 75 different pump models as well as countless replacement parts and accessories.

ABOVE:

The original headquarters of Simmons Machine and Tool Inc. founded by Clarence Simmons in Lubbock, Texas in 1951.

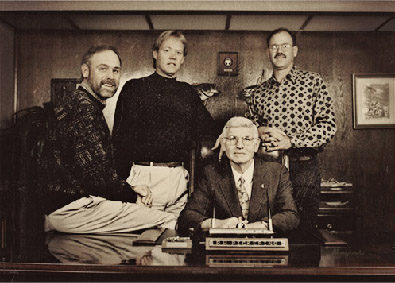

RIGHT:

Seated Raymond Pickering, 1997. From left to right, Raymond's sons: Jay, David and Don Pickering

About : UNMATCHED QUALITY

GO AGAINST THE CURRENT

WHILE IT CAN BE TEMPTING TO BECOME COMPLACENT WITH WHAT'S CUSTOMARY, WE REFUSE TO COMPROMISE ON OUR QUALITY STANDARDS.

About : UNMATCHED QUALITY

GO AGAINST THE CURRENT

WHILE IT CAN BE TEMPTING TO BECOME COMPLACENT WITH WHAT'S CUSTOMARY, WE REFUSE TO COMPROMISE ON OUR QUALITY STANDARDS.

As one of the last privately held vertical turbine manufacturers in the industry, SIMFLO’s leadership has maintained the same unmatched standards of quality and performance that the company was originally founded on. This results in the longest possible life for our pumps and a ripple effect ensuring the longevity of your operation.

That also means there’s less red tape to cut through. Decisions can be made quickly, and we are agile enough to pivot if your plans change. Our engineering department is equipped with the latest software and resources, and our in-house support team gives our customers direct access to experienced personnel to answer any questions which may arise.

From the top down, every decision is made with you, the customer, in mind

About : FOUNDRY

MEET OUR ALL-STAR CAST

CONTROLLING A WELL-CAST PRODUCT IS AN INCREDIBLE ADVANTAGE TO PRODUCING PUMPS THAT SURPASS ALL OTHERS.

About : FOUNDRY

MEET OUR ALL-STAR CAST

CONTROLLING A WELL-CAST PRODUCT IS AN INCREDIBLE ADVANTAGE TO PRODUCING PUMPS THAT SURPASS ALL OTHERS.

Every aspect of a SIMFLO pump is created to provide the highest level of performance in the industry. We keep pace with new technologies and continually improve our processes and equipment to maximize product availability and high-quality standards. The expert staff at SIMFLO understands the art of pouring metal and uses proven techniques to verify the quality of each cast piece. This attention to detail assures hydraulic performance and a product free of physical defect.